- Here's an overview of our services for Slitting Lines -

At GVK Designers Manufacturers and Consultants LLP, we take pride in offering comprehensive services for Slitting Lines. Slitting lines are crucial in the metal processing industry, enabling the precise and efficient cutting of coils into narrower strips or sheets. Our expertise in Slitting Lines covers a variety of applications, materials, and coil dimensions.

- Designing Slitting Lines: Our team of experienced engineers and designers will develop customized designs for Slitting Lines to match your specific requirements. Whether you need simple or complex slitting operations, we design the lines to ensure high productivity and accuracy.

- Manufacturing Slitting Equipment: With our manufacturing capabilities, we can produce various components and equipment necessary for Slitting Lines, such as slitter heads, recoilers, tension stands, and edge trimmers. We focus on quality and durability to ensure reliable and long-lasting equipment.

Installation and Commissioning: Our experts handle the installation and commissioning of Slitting Lines at your facility. We ensure precise alignment, setup, and calibration of the equipment to achieve accurate and consistent slitting operations.

Process Optimization: We provide consultancy services to optimize the slitting process in your lines. Our team will analyze your existing operations, identify areas for improvement, and offer recommendations to enhance efficiency, reduce waste, and maximize productivity.

Equipment Upgradation and Revamping: If you have existing Slitting Lines that require upgrades or improvements, we can assist you in enhancing their capabilities. Our team will assess your equipment, propose necessary modifications, and implement the changes to optimize performance and increase productivity.

Training and Support: We offer training programs for your operators to ensure they are proficient in operating and maintaining the Slitting Lines. Our support extends beyond installation to help you achieve seamless and reliable production.

Quality Assurance and Compliance: Quality assurance is integral to our services. We implement strict quality control processes to ensure that the Slitting Lines we design, manufacture, and install meet industry standards and your specific requirements.

# 1 Here are some key points about Slitting Lines

Slitting Lines are an essential component of the steel processing industry, particularly for transforming wide coils into narrower strips or slits of steel. They are used to cut wide coils into various narrower widths, providing versatility and meeting the specific size requirements of different industries

Purpose: The primary purpose of Slitting Lines is to convert large steel coils into smaller strips or slits of specific widths. This process enables manufacturers to produce coils in various sizes that cater to different applications.

Coil Handling: Slitting Lines are equipped with coil handling systems that efficiently handle the large steel coils. The coils are loaded onto the line, unwound, and guided through the slitting process.

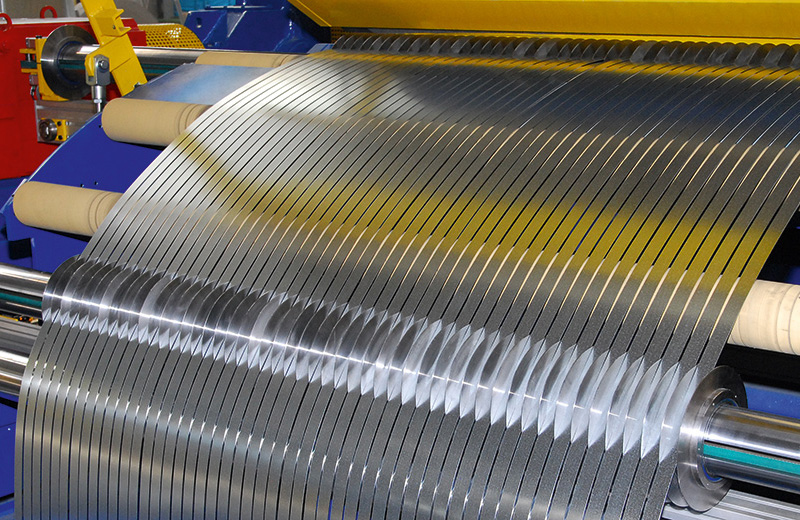

Slitting Process: The slitting process involves passing the steel coil through rotating circular knives or sets of blades, which make precise cuts to produce narrower strips or slits. The width of the slits can be adjusted according to customer requirements.

Slitter Head: The slitter head, which contains the circular knives or blades, is a crucial component of the Slitting Line. It can be set up to create multiple slits or strips simultaneously.

Tension Control: Tension control systems are used in Slitting Lines to ensure the proper tension is maintained throughout the process. Proper tension is crucial to prevent material damage and ensure consistent quality.

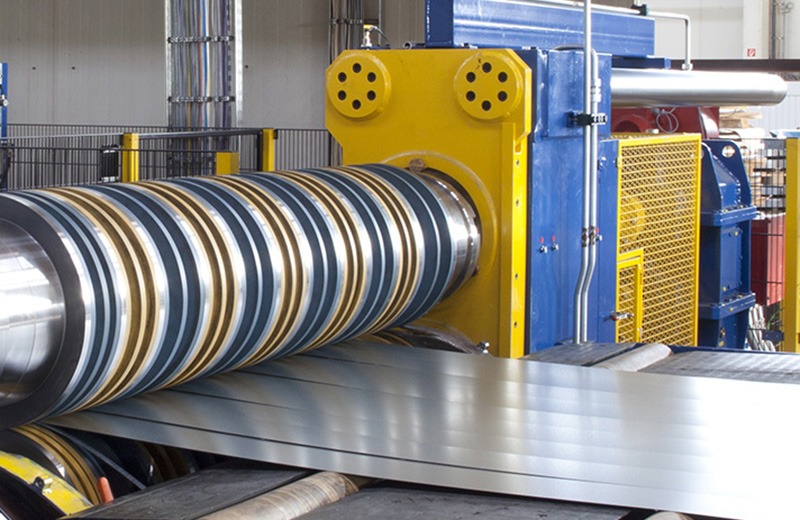

Recoiling: After slitting, the narrower strips are rewound into smaller coils of various widths. The recoiling process can include tension leveling to ensure uniform winding.

Quality Control: Slitting Lines incorporate advanced control and monitoring systems to maintain the quality of the slits. Parameters such as strip width, edge burr, and coil alignment are closely monitored to meet the required specifications.

Slit Coil Packaging: Slit coils are often packaged and labeled for easy identification and shipping to customers or downstream processes.

Slitting Lines are widely used in industries such as construction, automotive, appliance manufacturing, and more. They provide flexibility in producing a variety of slit sizes from a single large coil, optimizing material usage and reducing waste.

As a comprehensive service provider, GVK Designers Manufacturers and Consultants LLP may offer expertise in designing, manufacturing, installing, and commissioning Slitting Lines. Their services are likely to be tailored to meet the specific requirements of their clients, ensuring high-quality slit steel products that meet industry standards and customer needs.

At GVK Designers Manufacturers and Consultants LLP, we are committed to delivering efficient and high-quality Slitting Line solutions. We aim to exceed customer expectations by providing reliable services and tailored solutions that address your unique needs. Contact us today to discuss your Slitting Line requirements and leverage our expertise in this field.

#1 Here are some key aspects of Slitting Lines

Slitting Lines, also known as Slitting Machines or Slitters, are specialized equipment used in the steel and metal processing industry to slit or cut wide coils of metal into narrower strips. The process of slitting involves longitudinal cutting of the metal coil to achieve the desired width and dimensions. Slitting Lines play a crucial role in converting large coils into smaller, more manageable strips for various downstream applications.

Slitting Lines are vital in the metal processing industry, as they enable manufacturers to transform large coils of metal into smaller strips, suitable for a wide range of applications. The strips produced by Slitting Lines are used in various industries, including automotive, construction, electronics, appliances, and more. Slitting Lines ensure efficiency, accuracy, and versatility in metal processing operations.

Slitting Process: The primary function of Slitting Lines is to slit or cut wide coils of metal into narrower strips. The metal coil is fed into the slitter, and rotating circular knives or blades make longitudinal cuts along the length of the coil, creating multiple narrower strips.

Precision Slitting: Slitting Lines are designed for high precision slitting to achieve tight width tolerances on the produced strips. This precision is critical for applications where consistent strip width is essential.

Multiple Slits: Slitting Lines can be configured to create multiple slits simultaneously, producing several narrow strips from a single wide coil in a single pass. The number of slits depends on the number of circular knives or blades installed in the slitter.

Recoiling and Separating: After slitting, the narrower strips are recoiled into individual coils or separated into separate bundles, depending on the specific customer requirements and downstream applications.

Different Materials: Slitting Lines can handle various types of metal coils, including carbon steel, stainless steel, aluminum, copper, and other alloys.

Width Range: Slitting Lines can produce strips of different widths, depending on the slitting machine’s capabilities and the requirements of the end-user. They can produce narrow strips as well as wider ones.

High Production Rates: Slitting Lines are designed for high-speed production to efficiently process large volumes of metal coils into smaller strips.

Customization: Slitting Lines can be customized based on specific customer needs, including slitting width, coil diameter, strip thickness, and other parameters.

At GVK Designers Manufacturers and Consultants LLP, our Slitting lines are essential equipment used in metal processing industries to cut large coils of metal into narrower strips or coils of specific widths. Slitting lines offer several benefits that contribute to improved efficiency, increased productivity, and enhanced product quality.

#1 Here are the key advantages of using slitting lines

Precision Cutting: Slitting lines provide precise and accurate cutting of metal coils into narrow strips with consistent widths. This level of precision ensures uniformity in the final product, reducing waste and improving overall product quality.

Increased Productivity: Slitting lines enable continuous and high-speed processing of metal coils, resulting in increased productivity compared to manual or slower cutting methods. They help manufacturers meet tight production schedules and deliver products on time.

Customization: Slitting lines allow for the customization of metal strip widths according to specific customer requirements. This flexibility enables manufacturers to cater to a wide range of industries and applications.

Reduced Material Waste: By accurately cutting metal coils into narrower strips, slitting lines minimize material waste. This not only saves costs but also contributes to sustainable manufacturing practices by optimizing material utilization.

Versatility: Slitting lines can handle various types of metal coils, including steel, aluminum, copper, and others. They are suitable for a wide range of industries, from automotive to construction and packaging.

Improved Efficiency: Automated slitting lines reduce manual intervention, leading to improved efficiency in the cutting process. The automation ensures consistent cutting results and reduces the risk of errors.

Quick Setup and Changeovers: Many modern slitting lines feature quick setup and changeover capabilities. This allows manufacturers to switch between different coil sizes and strip widths rapidly, reducing downtime and maximizing production uptime.

Edge Trim Removal: Slitting lines often come with edge trimming units, which remove the excess material from the edges of the coils. This results in cleaner and more precise strip edges.

Safety Features: Slitting lines are designed with safety features to protect operators and personnel during the cutting process. Safety interlocks, guards, and emergency stop systems ensure a safe working environment.

Quality Control: Slitting lines often include quality control systems that inspect the finished strips for defects or inconsistencies. This allows manufacturers to maintain high-quality standards and deliver defect-free products to customers.

Integration with Downstream Processes: Slitting lines can be integrated seamlessly with other production processes, such as roll forming, stamping, or coating lines, enabling a streamlined manufacturing workflow.

Why Choose Us?

studied be luckily. Ourselves for determine attending how led gentleman sincerity.

When you choose GVK Designers & Consultants LLP, you can expect a dedicated team, innovative solutions, and a commitment to excellence. We are ready to partner with you to bring your vision to life and deliver outstanding results.

"Your Trusted Partner for Steel Plant Equipment: GVK Designers Manufacturers and Consultants LLP"

COMPANY

Manufacturing Dealings, Distributing Quality.

Our company is dedicated to providing exceptional manufacturing services that prioritize quality above all else. From our production process to our final distribution, every step we take is focused on delivering a superior product to our customers. Our team of skilled professionals work tirelessly to ensure our manufacturing dealings meet and exceed industry standards. We take pride in our ability to produce products with a level of precision and attention to detail that sets us apart from the competition. Our steadfast commitment to quality doesn’t stop at the factory door – we are equally dedicated to ensuring our products are distributed with the same level of excellence. That’s why we take every precaution to carefully pack, ship, and store our goods in order to ensure they arrive to our customers in pristine condition. Choose our company for all your manufacturing needs and rest easy knowing quality is always our top priority.

GVK Designers Manufacturers and Consultants LLP is a company that is dedicated to the growth of industrial sectors. We believe in empowering our clients and customers by providing them with high-quality products and services that meet their diverse needs and requirements. Our team of experts is always on the forefront when it comes to researching, designing, and manufacturing various products that are required by different industries and sectors. We are constantly innovating and improving our products and services to keep up with the latest trends and technologies in the industry. We understand that every customer is unique and has specific needs that must be met, which is why we work closely with our clients to find tailored solutions that fit their individual requirements. Our commitment to quality, integrity, and customer satisfaction is what sets us apart from our competitors and makes us the go-to choice for industrial growth.

GVK Designers Manufacturers and Consultants LLP is a company that is at the forefront of driving innovation and change in the manufacturing industry. Through their cutting-edge designs and innovative manufacturing processes, they are transforming the way products are made. Their commitment to excellence is unparalleled, and they work tirelessly to stay ahead of the curve when it comes to the latest technological advancements. Whether you are a small startup looking to bring your product to market, or a large corporation searching for a reliable manufacturing partner, GVK Designers Manufacturers and Consultants LLP has the expertise and experience necessary to help you achieve your goals. They understand the unique challenges that come with each project, and they are dedicated to providing customized solutions that meet your specific needs. Choose GVK Designers Manufacturers and Consultants LLP for all of your manufacturing needs, and experience the difference that innovation can make.

Are you in search of a reliable and efficient partner for commissioning solutions in the industrial sector? If so, look no further than GVK Designers Manufacturers and Consultants LLP. Our team of experts is dedicated to providing seamless and top-of-the-line commissioning solutions to ensure industrial success for our clients. With years of experience in the industry, we have the expertise and knowledge to customize our services to meet your specific needs and objectives. Our commitment to excellence and attention to detail is evident in every project we undertake, and we go above and beyond to ensure the success of our clients. Trust GVK Designers Manufacturers and Consultants LLP for your commissioning needs and experience the difference in our quality services.

That's great! GVK Designers Manufacturers and Consultants LLP offers a comprehensive range of services

Designing

GVK Designers Manufacturers and Consultants LLP specializes in designing various products, systems, or components. This can include conceptualizing, creating technical drawings, and developing specifications based on client requirements.

Manufacturing

The company is involved in the manufacturing process of various equipment, products, or systems. They have expertise in producing high-quality items using advanced techniques and technologies.

Installation

GVK Designers Manufacturers and Consultants LLP offers installation services, ensuring that the products they manufacture are properly and securely installed at the client's location. This involves skilled technicians who are proficient in setting up equipment or systems.

Commissioning

Commissioning involves the process of testing and ensuring that the installed equipment or systems are functioning correctly and meeting the specified requirements. GVK Designers Manufacturers and Consultants LLP can assist in commissioning activities to verify the performance and functionality of their products.

Equipment Upgradation

The company provides services to upgrade existing equipment or systems to improve their performance, efficiency, or capabilities. This can involve replacing outdated components, incorporating new technologies, or enhancing functionality.

Equipment Revamping

GVK Designers Manufacturers and Consultants LLP also offers revamping services, which involve significant modifications or improvements to existing equipment or systems. This can include structural changes, functional enhancements, or modernization to extend the lifespan or enhance the performance of the equipment.

Consultancy Services

Along with their manufacturing capabilities, GVK Designers Manufacturers and Consultants LLP provides consultancy services. They offer expert advice, guidance, and solutions related to designing, manufacturing, installation, commissioning, equipment upgradation, or revamping. These consultancy services aim to assist clients in making informed decisions and achieving their objectives effectively.

Certainly! Here are some frequently asked questions (FAQs) about GVK Designers Manufacturers and Consultants LLP:

GVK Designers Manufacturers and Consultants LLP serves a wide range of industries, including but not limited to manufacturing, steel, automotive, energy, construction, and infrastructure. We have experience working with diverse sectors and can tailor our services to meet specific industry requirements.

Yes, we have the capability to handle projects of varying scales. Whether you have a small-scale project requiring specific equipment or a large-scale project involving multiple systems, we can provide customized solutions to meet your needs.

To request a quote, you can reach out to us via phone or email with your project details and requirements. Our team will review the information and provide you with a comprehensive quote tailored to your specific needs.

Yes, we can provide references and examples of our past projects upon request. We have successfully completed numerous projects in the past, and we can share relevant case studies or testimonials to showcase our expertise and track record.

The duration of the design and manufacturing process can vary depending on the complexity of the project, the scope of work, and other factors. Once we understand your project requirements, we can provide you with an estimated timeline and keep you updated on the progress throughout the process.

Yes, we provide after-sales support and maintenance services to ensure the optimal performance and longevity of the equipment or systems we deliver. Our team can assist with regular maintenance, troubleshooting, and addressing any issues that may arise after installation.

Yes, our services are available internationally. We have experience working with clients from various countries, and we can provide our services globally based on project requirements.

"Realize Your Vision with GVK Designers & Consultants LLP!"

At GVK Designers & Consultants LLP, we are dedicated to helping you bring your vision to life. With our expertise in engineering and design, we offer a range of services tailored to meet your specific needs.