"Transforming Visions into Reality: Infrastructure Innovations by GVK Designers, Manufacturers, and Consultants LLP"

“Empowering Progress, Enabling Solutions: GVK Designers Manufacturers and Consultants LLP – Building the Path to Success”

our Infrastructure

Precision Engineering Excellence at GVK Designers Manufacturers & Consultants LLP

At GVK Designers Manufacturers & Consultants LLP, we are the driving force behind cutting-edge infrastructure solutions. With an unwavering commitment to innovation and quality, our expertise spans the realms of CNC, VMC, lathe machines, and drilling technologies.

Our Infrastructure division stands as a testament to our dedication to engineering excellence. Equipped with state-of-the-art CNC and VMC machinery, we bring dreams to life through precision and meticulous craftsmanship. Our lathe machines shape the foundations of tomorrow, while our drilling technology paves the way for progress.

Behind these remarkable feats stands our exceptional team, whose skills and dedication breathe life into every project. With a shared passion for pushing boundaries, we take pride in crafting solutions that stand as benchmarks in the industry.

From concept to realization, we navigate the intricacies of infrastructure, bringing innovation and efficiency to the forefront. GVK Designers Manufacturers & Consultants LLP: Where Infrastructure Meets the Future, Powered by Precision.”

At GVK Designers Manufacturers & Consultants LLP, we have a robust and advanced infrastructure that empowers us to excel in various precision machining processes. Our state-of-the-art facilities include cutting-edge machinery and equipment, enabling us to deliver high-quality components and products.

CNC (Computer Numerical Control) Machining: Our CNC machining section is equipped with modern CNC machines that offer exceptional accuracy and precision. These machines are programmed to execute intricate machining tasks with consistent results, ensuring high-quality components.

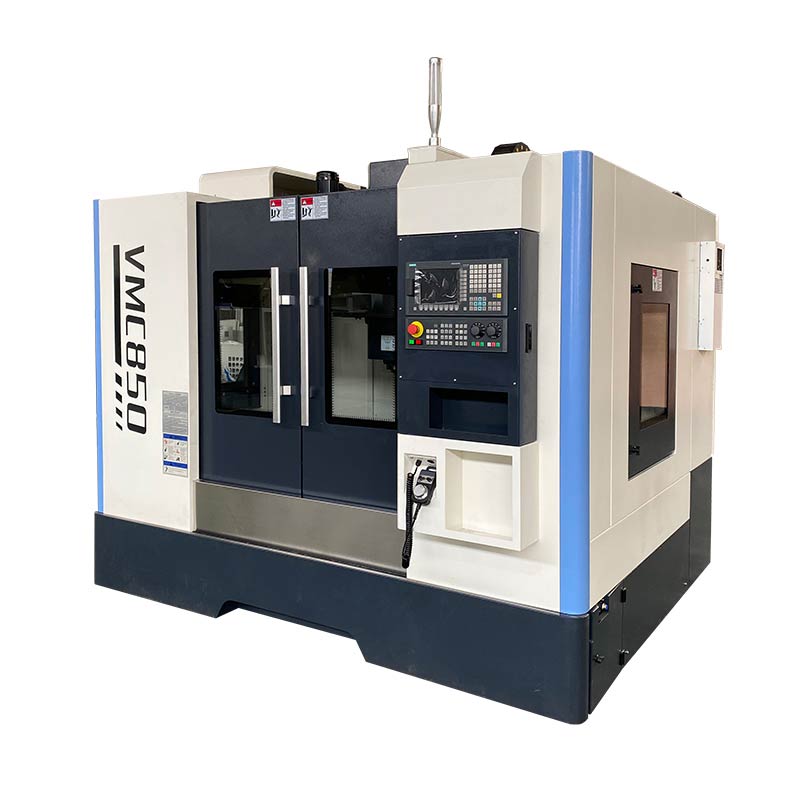

VMC (Vertical Machining Center): Our VMC section features advanced vertical machining centers that are capable of performing multi-axis operations. These machines are vital for creating complex geometries and achieving tight tolerances.

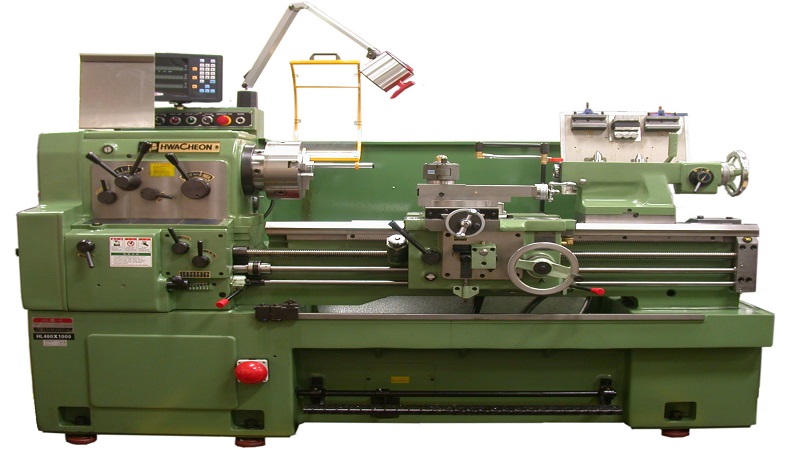

Lathe Machines: Our lathe machines play a crucial role in turning and shaping raw materials into intricate components. With both conventional and modern CNC-controlled lathes, we can efficiently produce a wide range of parts.

Drilling Machines: Our drilling machines are used for creating precise holes in components. Whether it’s single-point drilling or multi-axis drilling, our equipment ensures accuracy and consistency.

Quality Control: We have a dedicated quality control section equipped with measurement tools and instruments for inspecting the dimensions and tolerances of machined components. This ensures that the products meet the required specifications.

Skilled Workforce: Our team of skilled machinists, technicians, and engineers are experienced in operating and maintaining these advanced machines. Their expertise guarantees the quality and precision of the finished products.

Manufacturing Planning: Our efficient manufacturing planning process ensures that each machine is optimally utilized, minimizing downtime and maximizing productivity.

Research and Innovation: We are committed to staying updated with the latest machining technologies and methodologies. Our research and innovation efforts keep us at the forefront of the industry.

Continuous Improvement: We follow a continuous improvement approach, regularly upgrading our machinery, adopting new techniques, and refining processes to enhance efficiency and quality.

Safety Measures: Safety is paramount in our operations. We strictly adhere to safety guidelines and maintain a secure working environment for our employees.

At GVK Designers Manufacturers & Consultants LLP, our infrastructure serves as the backbone of our operations. It allows us to deliver precision-machined components that meet the highest industry standards. We are dedicated to providing innovative solutions and ensuring customer satisfaction through the utilization of our advanced machinery and expertise.

That sounds impressive! GVK Designers Manufacturers and Consultants LLP seems to be a well-established and experienced engineering company with a diverse range of capabilities in designing, manufacturing, and commissioning equipment for non-ferrous industries. Your expertise in turnkey projects, installation, and re-conditioning of equipment, along with the ability to undertake re-design and upgradation of lines and equipment, showcases a comprehensive suite of services.

The fact that each of your directors holds around 25 years of experience in the industry speaks to the depth of knowledge and professionalism within your organization. This experience likely contributes to your ability to develop innovative and cost-effective designs, which are not only long-lasting but also energy-efficient and user-friendly.

With such a strong foundation of technical qualifications and a track record of successful projects, GVK Designers Manufacturers and Consultants LLP appears to be well-equipped to meet the demands of various clients in the non-ferrous industries. Your focus on innovation and efficiency should be valuable assets in today’s competitive market.

At GVK Designers Manufacturers & Consultants LLP, we take pride in our advanced infrastructure that supports our various manufacturing and consultancy services. Our infrastructure is equipped with modern machinery and tools that enable us to deliver high-quality solutions to our clients.

CNC (Computer Numerical Control) Machines: Our CNC machines are equipped with computerized controls that allow for precise and automated machining operations. These machines can perform intricate and complex tasks with high accuracy and efficiency.

VMC (Vertical Machining Center): VMCs are versatile machining centers that use a vertically oriented spindle to perform various milling operations. They are capable of handling a wide range of cutting tasks and are commonly used for creating intricate shapes and features.

Lathes: Our lathe machines are crucial for turning operations. They can shape workpieces by rotating them against a cutting tool, allowing us to create cylindrical or conical shapes with high precision.

Cutting and Fabrication Tools: Our infrastructure includes a variety of cutting tools and fabrication equipment that enable us to shape and modify materials to meet specific design requirements.

Quality Control and Measurement Tools: We also have advanced measurement and quality control equipment to ensure that our products meet the required specifications. This includes tools for dimensional accuracy, surface finish, and other quality parameters.

Skilled Workforce: Along with modern machinery, our skilled workforce is the backbone of our infrastructure. Our team consists of experienced engineers, technicians, and consultants who are well-versed in using the equipment and delivering top-notch services.

Safety Measures: Our infrastructure also includes safety measures and protocols to ensure the well-being of our workforce and the integrity of our operations.

At GVK Designers Manufacturers & Consultants LLP, our well-equipped infrastructure allows us to provide a wide range of services, from designing and manufacturing to installation, commissioning, and consultancy. We are committed to delivering excellence and meeting the diverse needs of our clients across various industries.

It sounds like GVK Designers Manufacturers & Consultants LLP has a well-rounded infrastructure to cater to various machining and manufacturing needs.

CNC machines are automated milling, turning, and machining tools that are controlled by computer programs. They offer high precision and can produce complex shapes and designs with consistent accuracy.

VMCs are a type of CNC machine that operates with a spindle mounted vertically. They are commonly used for tasks like drilling, milling, and cutting complex shapes from various materials.

Lathes are machines used for turning, facing, and producing cylindrical components. They can create symmetrical parts by rotating the workpiece against a cutting tool.

Drilling machines are used for creating holes in various materials. Depending on the type, they can be used for precision drilling or heavy-duty drilling tasks.

Having these capabilities in CNC, VMC, lathe machines, and drilling machines indicates that your company can handle a diverse range of machining tasks. These technologies are vital in various industries, including manufacturing, aerospace, automotive, and more. The precision and efficiency they offer can contribute to the overall quality of the products you manufacture or the services you provide.

Remember, the success of your operations not only depends on the equipment but also on the skills and expertise of your team members operating these machines. This combination of technology and skilled professionals likely positions GVK Designers Manufacturers & Consultants LLP as a competitive player in the manufacturing and machining sector.

“Empowering Progress, Enabling Solutions: GVK Designers Manufacturers and Consultants LLP – Building the Path to Success”

The infrastructure of a company refers to the physical and virtual assets, facilities, and systems that support its operations, processes, and technology needs. Here are some common elements of a company’s infrastructure:

This includes office buildings, manufacturing plants, warehouses, distribution centers, and any other physical locations that the company operates from.

The IT infrastructure comprises hardware, software, networks, and data centers that support the company’s information technology needs. This may include servers, routers, switches, computers, databases, and other IT equipment.

This includes phone systems, internet connectivity, email servers, and other communication tools that facilitate internal and external communication.

For companies involved in manufacturing, their infrastructure would include machinery and equipment used in the production process.

If the company deals with the transportation and distribution of goods, its infrastructure would include vehicles, transportation networks, and logistical systems.

Infrastructure also involves access to reliable power supply, water, and other utilities required for day-to-day operations.

This includes security systems, access controls, fire safety systems, and measures to ensure the safety of employees and assets.

Infrastructure includes storage facilities or warehouses where raw materials or finished products are stored.

This encompasses the software and databases used to manage various aspects of the business, including inventory, customer information, financial data, and more.

The company’s infrastructure also includes the human resources department, responsible for managing employees, training, and other HR functions.

This includes systems and processes for managing financial transactions, accounting, and budgeting.

For some industries, infrastructure includes measures to ensure environmental compliance and sustainability.

The specific infrastructure components and scale of your company’s infrastructure will depend on its size, industry, and operational needs. Companies continually invest in their infrastructure to stay competitive, improve efficiency, and support business growth.

At GVK Designers Manufacturers and Consultants LLP, we take pride in having a state-of-the-art infrastructure that enables us to deliver high-quality engineering solutions and services to our clients. Our infrastructure is designed to support the entire project lifecycle, from conceptualization and design to manufacturing, installation, and after-sales support. Here’s an overview of our infrastructure:

Design and Engineering Department: Our design and engineering team is equipped with the latest software tools and technologies to develop customized and innovative solutions for various engineering projects. We utilize computer-aided design (CAD) and simulation software to create accurate and optimized designs.

Manufacturing Facilities: We have modern and well-equipped manufacturing facilities that enable us to produce a wide range of equipment and components for various industries. Our manufacturing processes adhere to industry standards and emphasize quality and precision.

Testing and Quality Control: To ensure the reliability and performance of our products, we have a dedicated testing and quality control department. We conduct rigorous testing and inspection of our equipment to meet stringent quality standards and compliance requirements.

Installation and Commissioning Team: Our skilled installation and commissioning team is experienced in handling the setup and integration of complex engineering systems. We ensure proper alignment, calibration, and functionality to achieve optimal performance.

Research and Development: We have a dedicated research and development team that continuously explores new technologies and innovations in the engineering field. This allows us to stay at the forefront of industry advancements and provide cutting-edge solutions to our clients.

Project Management: Our project management team ensures smooth and efficient execution of projects. They monitor timelines, resource allocation, and progress to ensure timely delivery of projects.

After-Sales Support: We have a customer support and service department that provides ongoing assistance and support to our clients after the installation of equipment. We aim to maintain a long-term relationship with our clients and offer prompt and reliable after-sales services.

Safety and Compliance: At GVK Designers Manufacturers and Consultants LLP, we prioritize safety in all aspects of our operations. We adhere to industry safety standards and compliance guidelines to ensure the well-being of our employees and clients.

When you choose GVK Designers & Consultants LLP, you can expect a dedicated team, innovative solutions, and a commitment to excellence. We are ready to partner with you to bring your vision to life and deliver outstanding results.

We believe that our success is built upon the dedication and hard work of each team member. Our collaborative culture fosters creativity, innovation, and a strong sense of responsibility towards the communities we serve. Together, we strive to exceed expectations, solve complex challenges, and leave a lasting positive impact on the world.

With a strong focus on sustainability and environmental responsibility, our team members continuously explore new technologies and approaches to ensure that our infrastructure projects align with the needs of today and tomorrow.